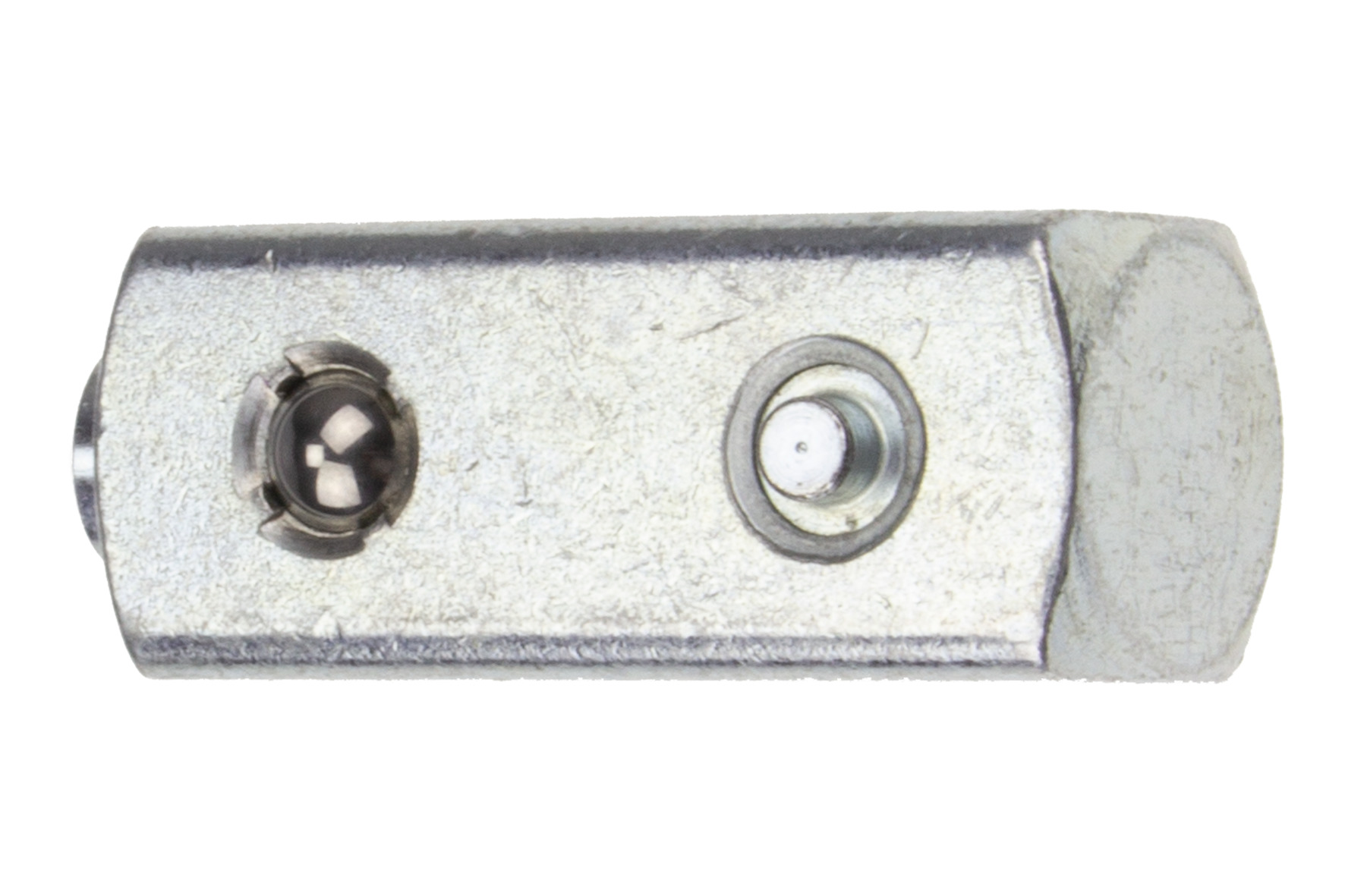

2450 Hexagon metric socket

Chrome-vanadium-steel, chrome plated, hole for ball bearing.

| Item No | Designation | Standard | Type | Inch | Weight | Length | Wrench size |

|---|---|---|---|---|---|---|---|

| 245019 | Hexagon metric socket 19 mm | DIN 3124, ISO 2725 | Hexagonal | 3/4 " | 174 g | 51 mm | 19 mm |

| 245021 | Hexagon metric socket 21 mm | DIN 3124, ISO 2725 | Hexagonal | 3/4 " | 180 g | 51 mm | 21 mm |

| 245022 | Hexagon metric socket 22 mm | DIN 3124, ISO 2725 | Hexagonal | 3/4 " | 200 g | 51 mm | 22 mm |

| 245024 | Hexagon metric socket 24 mm | DIN 3124, ISO 2725 | Hexagonal | 3/4 " | 210 g | 51 mm | 24 mm |

| 245026 | Hexagon metric socket 26 mm | DIN 3124, ISO 2725 | Hexagonal | 3/4 " | 230 g | 51 mm | 26 mm |

| 245027 | Hexagon metric socket 27 mm | DIN 3124, ISO 2725 | Hexagonal | 3/4 " | 230 g | 51 mm | 27 mm |

| 245030 | Hexagon metric socket 30 mm | DIN 3124, ISO 2725 | Hexagonal | 3/4 " | 290 g | 51 mm | 30 mm |

| 245032 | Hexagon metric socket 32 mm | DIN 3124, ISO 2725 | Hexagonal | 3/4 " | 310 g | 51 mm | 32 mm |

| 245036 | Hexagon metric socket 36 mm | DIN 3124, ISO 2725 | Hexagonal | 3/4 " | 450 g | 51 mm | 36 mm |

| 245038 | Hexagon metric socket 38 mm | DIN 3124, ISO 2725 | Hexagonal | 3/4 " | 480 g | 51 mm | 38 mm |

| 245041 | Hexagon metric socket 41 mm | DIN 3124, ISO 2725 | Hexagonal | 3/4 " | 540 g | 51 mm | 41 mm |

| 245046 | Hexagon metric socket 46 mm | DIN 3124, ISO 2725 | Hexagonal | 3/4 " | 690 g | 51 mm | 46 mm |

| 245050 | Hexagon metric socket 50 mm | DIN 3124, ISO 2725 | Hexagonal | 3/4 " | 750 g | 51 mm | 50 mm |

| 245055 | Hexagon metric socket 55 mm | DIN 3124, ISO 2725 | Hexagonal | 3/4 " | 953 g | 51 mm | 55 mm |

| 245060 | Hexagon metric socket 60 mm | DIN 3124, ISO 2725 | Hexagonal | 3/4 " | 1091 g | 51 mm | 60 mm |

Manufacturer information (GPSR)

MANUFACTURER ACCORDING TO THE EU GENERAL PRODUCT SAFETY REGULATION (GPSR)

STUBAI ZMV GmbH

Dr. Kofler Straße 1

A-6166 Fulpmes

Phone: +43 5225 6960 211

Email: office@stubai.com

Safety Instructions for Screw Tools (e.g. Screwdriver Bits)

General Information:

• Partially subject to standards DIN 3124, ISO 2725, or DIN 3124, DIN 3120C, ISO 1174-1 or DIN 3120, ISO 1174, D 6.3 or DIN 3121.

• Screw tools may only be used by persons with limited physical, sensory or mental abilities, or lacking experience and/or knowledge, if they are supervised by a person responsible for their safety, have received instructions on how to use screw tools, and have understood the resulting hazards.

• Children may only use screw tools if they are over 8 years old and are supervised by a person responsible for their safety, have received instructions on how to use screw tools, and have understood the resulting hazards.

• Keep packaging films away from children; risk of suffocation!

Intended Use:

• Safety is only ensured when the tool is used as intended. Use screw tools exclusively for their designated purpose. Incorrect use may lead to tool breakage and injuries.

Improper Use:

• Use as a chisel, hammer or lever is not permitted.

Inspection Before Use:

• Ensure tool integrity: Check all screw tools before use for visible damage such as breaks or loose parts.

• Do not use damaged screw tools: Defective screw tools must not be used, as they increase the risk of accidents.

• Observe compatibility: Ensure that the screwdriver bit is compatible with the screwdriver or drill being used. Improper tools may cause slipping, tool breakage or damage.

Personal Protective Equipment:

• Wear safety goggles: Use safety goggles to protect yourself from chipping material.

• Hand protection: Wear robust work gloves that provide a secure grip and protect against skin injuries.

• Safety footwear: Wear safety shoes with a metal or plastic toe cap to protect your toes.

Specific Safety Instructions During Use:

• Ensure a firm connection: Make sure the screwdriver bit is firmly seated in the screwdriver or drill chuck before starting work. A loose bit may slip and cause injuries.

• Turn screws in the correct direction: Always turn the screw in the correct direction to avoid twisting or breaking the bit.

• Avoid overloading: Do not apply excessive pressure to the screw tool. Too much pressure may damage the bit or the screw, preventing proper engagement.

• Handle the tool carefully: Ensure that the screwdriver bit does not fall or come into contact with hard surfaces during handling to avoid damage.

Maintenance, Care and Storage:

• Regular inspection: Check the condition of the screwdriver bit regularly for wear or damage. A worn or damaged bit may impair work and increase the risk of injury.

• Cleaning after use: Screw tools should be cleaned regularly after use to remove dirt or oil residues. Regular cleaning ensures long service life and better tool performance.

• Rust protection: Protect metal parts from moisture to prevent rust. Apply rust protection if necessary.

• Storage: Store screw tools out of reach of children and persons with limited physical, sensory or mental abilities, in a safe, dry place such as a toolbox or tool wall to prevent accidents and damage.

Special Notes:

• Use only with matching screws: Screwdriver bits should only be used with the correct screw types. Using the wrong bit may damage both the bit and the screw material.

• Transport: Ensure that tools are securely fastened during transport and that sharp edges are protected to avoid injuries.

This text has been partially translated with the support of AI technology.

STUBAI ZMV GmbH

Dr. Kofler Straße 1

A-6166 Fulpmes

Phone: +43 5225 6960 211

Email: office@stubai.com

Safety Instructions for Screw Tools (e.g. Screwdriver Bits)

General Information:

• Partially subject to standards DIN 3124, ISO 2725, or DIN 3124, DIN 3120C, ISO 1174-1 or DIN 3120, ISO 1174, D 6.3 or DIN 3121.

• Screw tools may only be used by persons with limited physical, sensory or mental abilities, or lacking experience and/or knowledge, if they are supervised by a person responsible for their safety, have received instructions on how to use screw tools, and have understood the resulting hazards.

• Children may only use screw tools if they are over 8 years old and are supervised by a person responsible for their safety, have received instructions on how to use screw tools, and have understood the resulting hazards.

• Keep packaging films away from children; risk of suffocation!

Intended Use:

• Safety is only ensured when the tool is used as intended. Use screw tools exclusively for their designated purpose. Incorrect use may lead to tool breakage and injuries.

Improper Use:

• Use as a chisel, hammer or lever is not permitted.

Inspection Before Use:

• Ensure tool integrity: Check all screw tools before use for visible damage such as breaks or loose parts.

• Do not use damaged screw tools: Defective screw tools must not be used, as they increase the risk of accidents.

• Observe compatibility: Ensure that the screwdriver bit is compatible with the screwdriver or drill being used. Improper tools may cause slipping, tool breakage or damage.

Personal Protective Equipment:

• Wear safety goggles: Use safety goggles to protect yourself from chipping material.

• Hand protection: Wear robust work gloves that provide a secure grip and protect against skin injuries.

• Safety footwear: Wear safety shoes with a metal or plastic toe cap to protect your toes.

Specific Safety Instructions During Use:

• Ensure a firm connection: Make sure the screwdriver bit is firmly seated in the screwdriver or drill chuck before starting work. A loose bit may slip and cause injuries.

• Turn screws in the correct direction: Always turn the screw in the correct direction to avoid twisting or breaking the bit.

• Avoid overloading: Do not apply excessive pressure to the screw tool. Too much pressure may damage the bit or the screw, preventing proper engagement.

• Handle the tool carefully: Ensure that the screwdriver bit does not fall or come into contact with hard surfaces during handling to avoid damage.

Maintenance, Care and Storage:

• Regular inspection: Check the condition of the screwdriver bit regularly for wear or damage. A worn or damaged bit may impair work and increase the risk of injury.

• Cleaning after use: Screw tools should be cleaned regularly after use to remove dirt or oil residues. Regular cleaning ensures long service life and better tool performance.

• Rust protection: Protect metal parts from moisture to prevent rust. Apply rust protection if necessary.

• Storage: Store screw tools out of reach of children and persons with limited physical, sensory or mental abilities, in a safe, dry place such as a toolbox or tool wall to prevent accidents and damage.

Special Notes:

• Use only with matching screws: Screwdriver bits should only be used with the correct screw types. Using the wrong bit may damage both the bit and the screw material.

• Transport: Ensure that tools are securely fastened during transport and that sharp edges are protected to avoid injuries.

This text has been partially translated with the support of AI technology.