S2839 Tinsmith’s set, 40 pcs. without tool case

complete roofer set for all installation use with metals and faciapanels.

| Item No | Designation | Weight |

|---|---|---|

| S283940 | Tinsmith's set, 40 pcs. without tool case | 20331 g |

Set Items

| Image | Item No | Designation |

|---|---|---|

| 170003 | Mechanics screwdriver 3,5/100 |

| 170004 | Mechanics screwdriver 4/100 |

| 170005 | Mechanics screwdriver 5,5/125 |

| 171002 | Phillips screwdriver 1/80 |

| 171004 | Phillips screwdriver 2/100 |

| 103902 | Flat chisel or electrician's chisel 10 mm |

| 442002 | Plumb bobs, pear shaped 250 g |

| 443125 | Mason cord 50 m, Ø 2,5 mm |

| 116101 | Bearing scraper 125 mm |

| 354326 | Chisel with black plastic handle 26 mm |

| 444104 | Marking pencil for sheet metal, glass, ceramics 175 mm |

| 250003 | Dividers 200 mm |

| 262001 | Scriber, curved 250 mm |

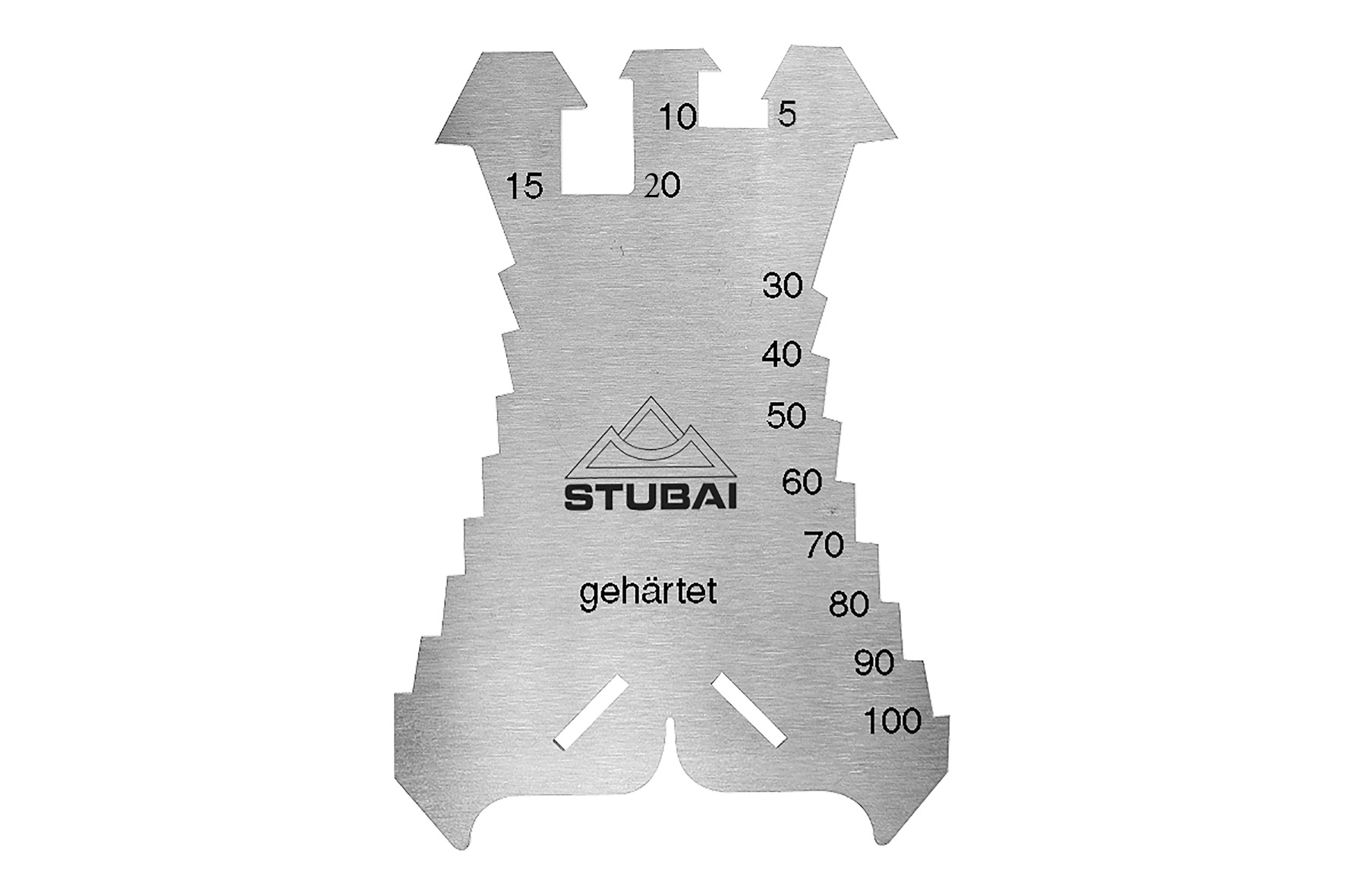

| 278601 | Marking template, hardened, stainless 140 mm |

| 270501 | Combination tin snips 280 mm |

| 270001 | Combination tin snips 280 mm |

| 269001 | Pelican pattern snips, right, 350 mm |

| 100404 | Engineer's hammer with ash handle 200 g |

| 100406 | Engineer's hammer with ash handle 300 g |

| 100408 | Engineer's hammer with ash handle 500 g |

| 282002 | Tinsmith‘s seaming pliers, straight 60 mm |

| 282102 | Tinsmith‘s seaming pliers, 45° bent 60 mm |

| 282201 | Tinsmith‘s seaming pliers, 90° 60 mm |

| 282451 | Seaming pliers for corners 280 mm |

| 279501 | Seam opening pliers 250 mm |

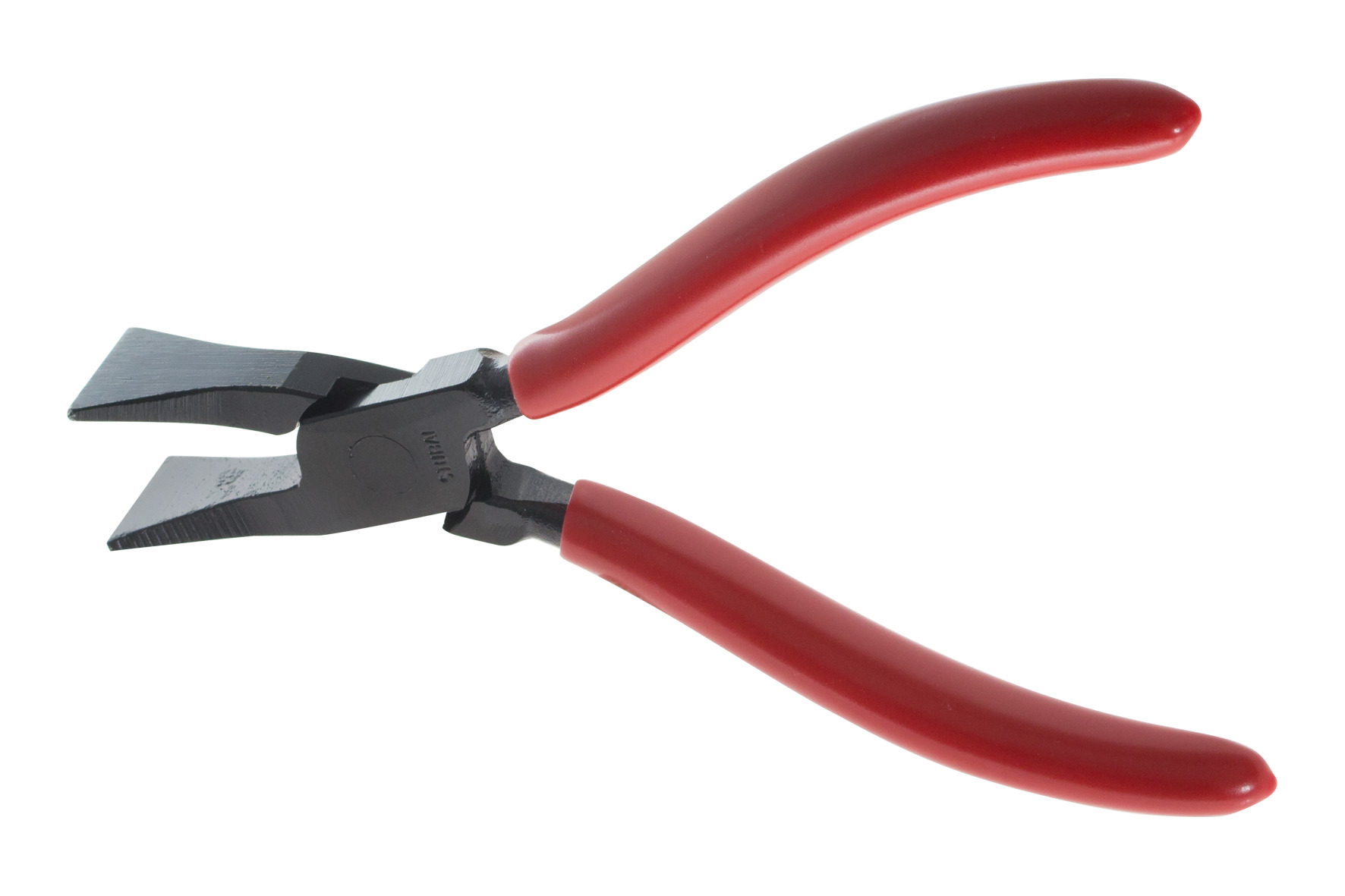

| 280001 | Tinsmith‘s flat nose pliers 240 mm |

| 281001 | Tinsmith‘s round nose pliers 240 mm |

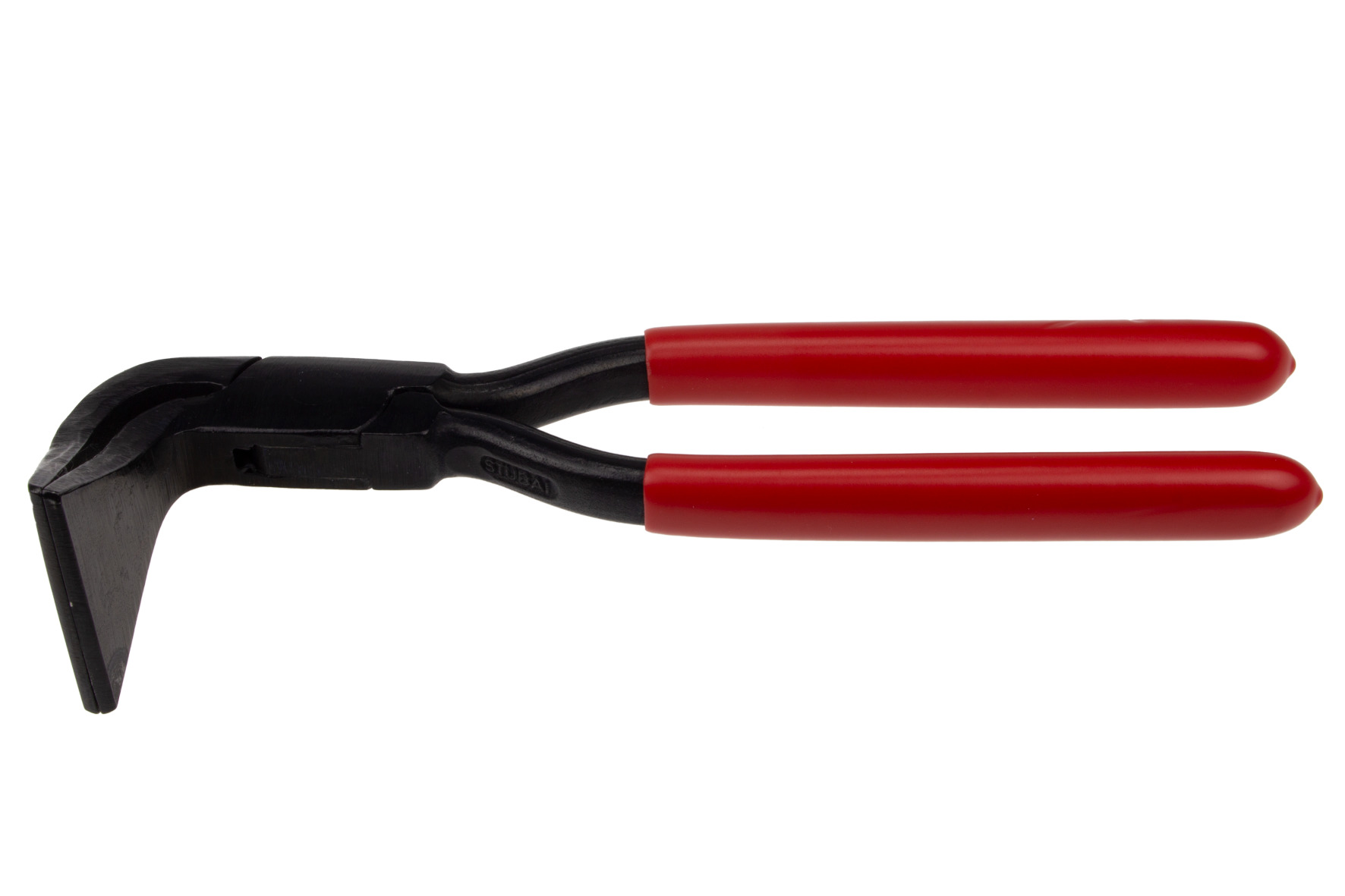

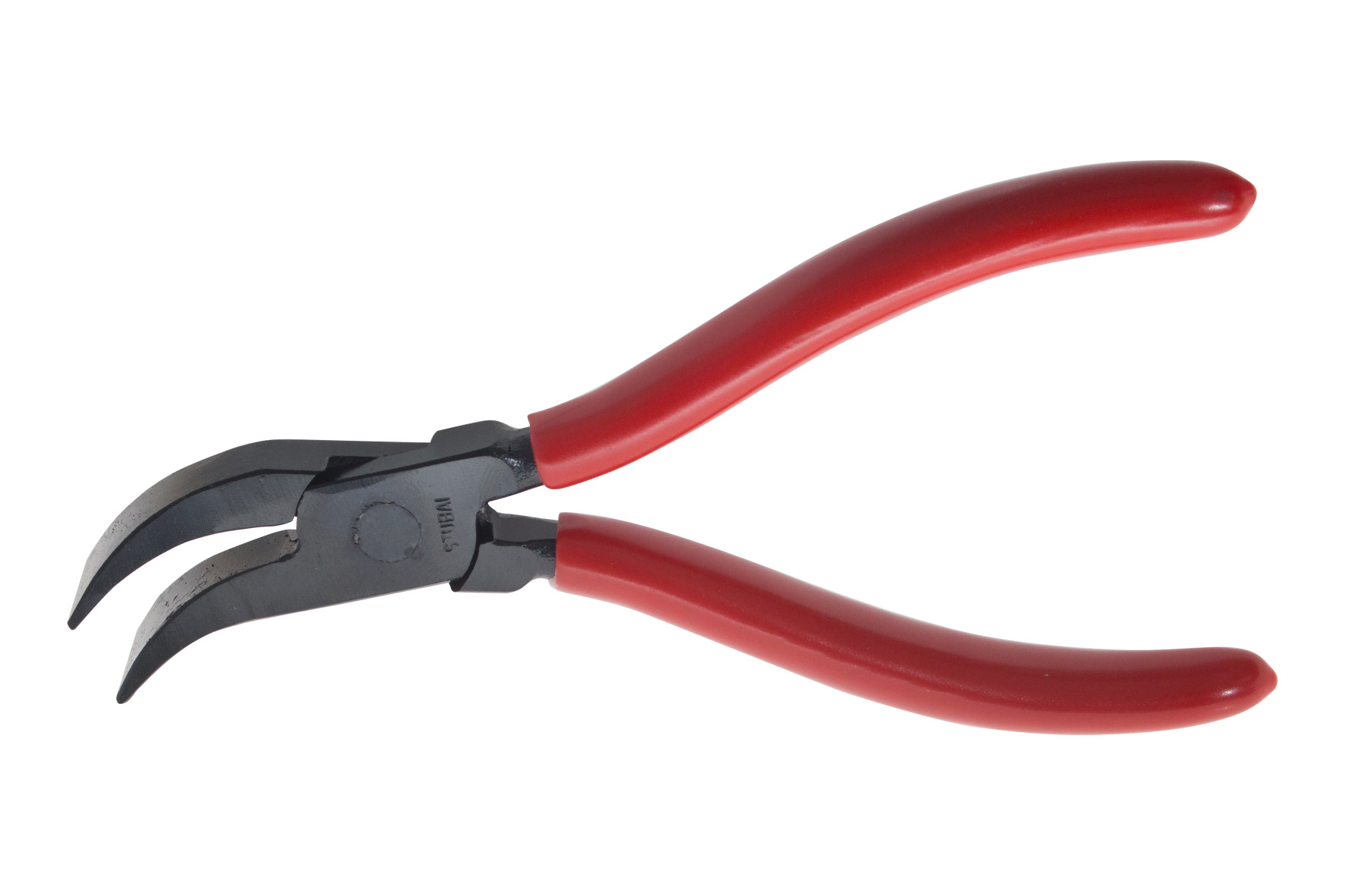

| 279101 | Gutter pliers 250 mm |

| 107905 | Pincers 200 mm |

| 282901 | Tinsmith‘s seaming pliers, straight piccolo pattern 180 mm |

| 283001 | Tinsmith‘s seaming pliers, 30° bent, piccolo pattern 180 mm |

| 272011 | Hacksaw |

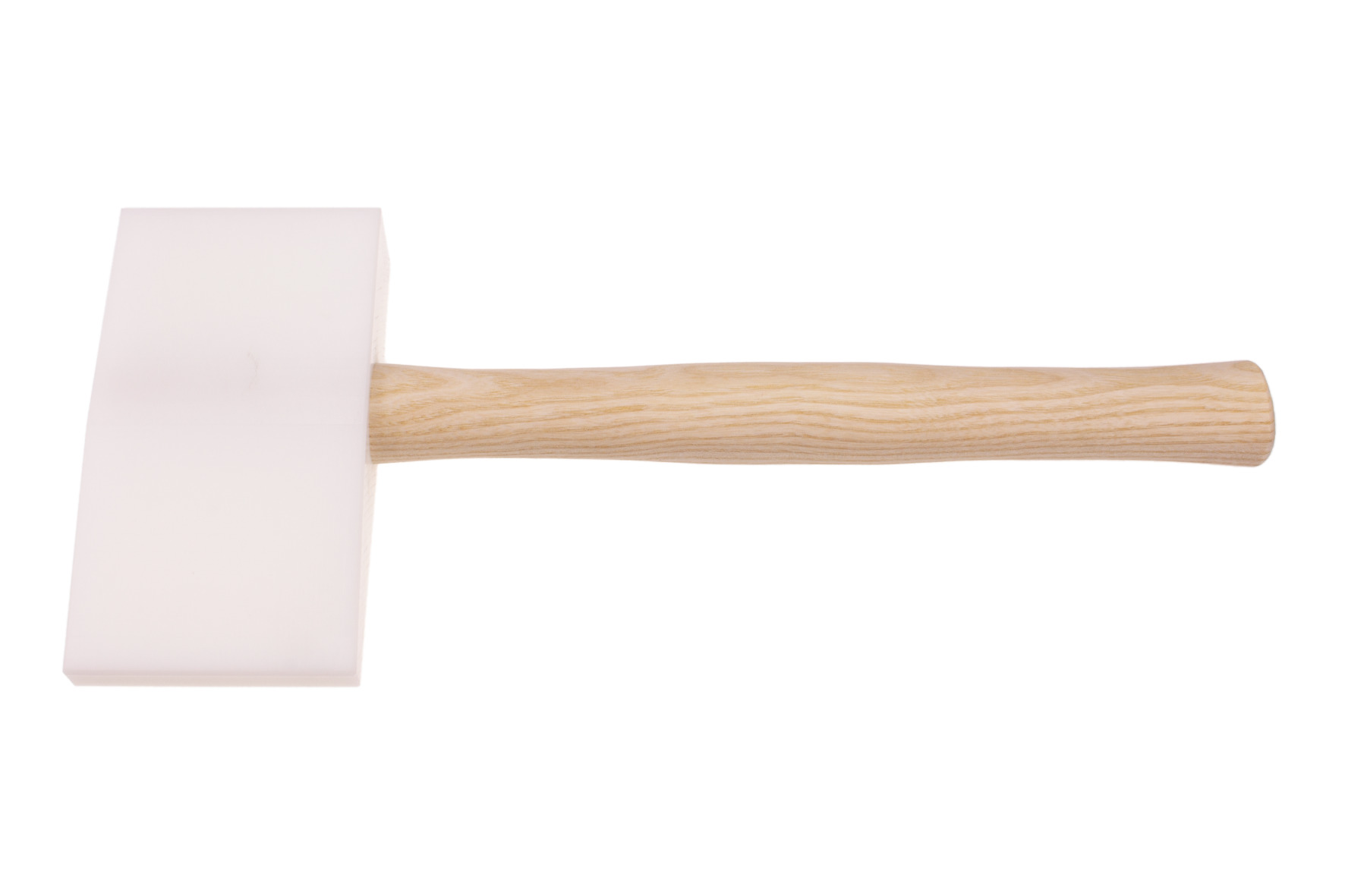

| 278501 | Plastic faced hammer, wedge shaped 155 mm |

| 278504 | Plastic faced hammer, rectangular, coloured 155 mm |

| 278401 | Pocket pan former 140 mm |

| 278201 | Corner roofing seamer 140 mm |

| 278101 | Double roofing seamer 140 mm |

| 278002 | Roofing seamer, straight 140 mm |

| 263105 | Engineer‘s steel square with stock support 300 mm |

| 111102 | End cutting nippers 160 mm |

Manufacturer information (GPSR)

MANUFACTURER ACCORDING TO THE EU GENERAL PRODUCT SAFETY REGULATION (GPSR)

STUBAI ZMV GmbH

Dr. Kofler Straße 1

A-6166 Fulpmes

Phone: +43 5225 6960 211

Email: office@stubai.com

Safety Instructions for Seaming Tools

General Information:

• Suitable tool: Always use tools specifically designed for the respective task. Using an unsuitable tool increases the risk of accidents and can make the work more difficult.

• Seaming tools may only be used by persons with limited physical, sensory or mental abilities, or lacking experience and/or knowledge, if they are supervised by a person responsible for their safety, have received instructions on how to use seaming tools, and have understood the resulting hazards.

• Children may only use seaming tools if they are over 8 years old and are supervised by a person responsible for their safety, have received instructions on how to use seaming tools, and have understood the resulting hazards.

• Keep packaging films away from children; risk of suffocation!

Intended Use:

• Safety is only ensured when the tool is used as intended. Use the tool exclusively for its designated purpose. Incorrect use may lead to tool breakage and injuries.

• Use according to instructions: Seaming tools such as bossing hammers, seaming irons, seaming boards and plastic hammers may only be used for their intended applications. Improper use may cause damage to the tool or the workpiece.

Improper Use:

• Any use other than the intended use is considered improper and is not permitted.

Inspection Before Use:

• Ensure tool integrity: Check all seaming tools before use for visible damage such as cracks in the handle, bent blades, breaks or loose parts.

• Do not use damaged tools: Defective tools must not be used, as they increase the risk of accidents.

Personal Protective Equipment:

• Wear safety goggles: Use safety goggles to protect yourself from chipping material.

• Hand protection: Wear robust work gloves that provide a secure grip and protect against skin injuries.

• Safety footwear: Wear safety shoes with a metal or plastic toe cap to protect your toes.

Specific Safety Instructions During Use:

• Secure the workpiece: Ensure that the workpiece is securely fixed to prevent movement or slipping during work. Insufficiently secured workpieces may lead to inaccurate results or injuries.

• Distance from body and tool: When striking with a hammer or similar tools, maintain sufficient distance from your body to avoid injuries from possible rebound.

• Secure grip: Hold the seaming tool firmly to prevent slipping or uncontrolled movements. An insecure grip may cause the tool to slip and lead to injuries.

• Controlled strikes: When working with a hammer or similar tools, apply even, controlled strikes. Excessive or uncontrolled blows may damage the workpiece or destroy the tool.

• Correct use of the tool: Use the bossing hammer, seaming iron or plastic hammer only in the designated area of the workpiece to create precise seam lines. Using the tool in the wrong area may deform the workpiece.

Specific Instructions for Individual Tools:

• Bossing hammer: This tool is often used for working sheet metal or metals. Ensure that the surface being struck is evenly supported. Improper handling may deform the material or damage the tool.

• Seaming iron: When using a seaming iron for shaping or embossing metal, ensure that the workpiece is well supported. Strikes with excessive force may cause cracks in the material.

• Seaming board: The seaming board should always be used on a stable surface to ensure precise and safe seaming. Ensure proper storage before and after use.

• Plastic hammer: Often used with more delicate materials or for precise work. Ensure that the hammer head is intact and free from cracks to achieve an even impact.

Maintenance, Care and Storage:

• Regular inspection: Check the condition of seaming tools regularly, especially the striking surfaces and edges. Cracks or wear may render the tool unusable and increase the risk of injury.

• Cleaning after use: After each use, seaming tools must be cleaned thoroughly to remove residues. Dry the tool well to prevent rust formation.

• Storage: Store seaming tools out of reach of children and persons with limited physical, sensory or mental abilities, in a safe, dry place such as a toolbox or tool wall to prevent accidents and damage.

Special Notes:

• Avoid improvisation: Use seaming tools exclusively for their intended purpose. Using tools for unsuitable applications may lead to tool breakage or injuries.

• Transport: Ensure that seaming tools are securely fastened during transport and that sharp edges are protected to avoid injuries.

This text has been partially translated with the support of AI technology.

STUBAI ZMV GmbH

Dr. Kofler Straße 1

A-6166 Fulpmes

Phone: +43 5225 6960 211

Email: office@stubai.com

Safety Instructions for Seaming Tools

General Information:

• Suitable tool: Always use tools specifically designed for the respective task. Using an unsuitable tool increases the risk of accidents and can make the work more difficult.

• Seaming tools may only be used by persons with limited physical, sensory or mental abilities, or lacking experience and/or knowledge, if they are supervised by a person responsible for their safety, have received instructions on how to use seaming tools, and have understood the resulting hazards.

• Children may only use seaming tools if they are over 8 years old and are supervised by a person responsible for their safety, have received instructions on how to use seaming tools, and have understood the resulting hazards.

• Keep packaging films away from children; risk of suffocation!

Intended Use:

• Safety is only ensured when the tool is used as intended. Use the tool exclusively for its designated purpose. Incorrect use may lead to tool breakage and injuries.

• Use according to instructions: Seaming tools such as bossing hammers, seaming irons, seaming boards and plastic hammers may only be used for their intended applications. Improper use may cause damage to the tool or the workpiece.

Improper Use:

• Any use other than the intended use is considered improper and is not permitted.

Inspection Before Use:

• Ensure tool integrity: Check all seaming tools before use for visible damage such as cracks in the handle, bent blades, breaks or loose parts.

• Do not use damaged tools: Defective tools must not be used, as they increase the risk of accidents.

Personal Protective Equipment:

• Wear safety goggles: Use safety goggles to protect yourself from chipping material.

• Hand protection: Wear robust work gloves that provide a secure grip and protect against skin injuries.

• Safety footwear: Wear safety shoes with a metal or plastic toe cap to protect your toes.

Specific Safety Instructions During Use:

• Secure the workpiece: Ensure that the workpiece is securely fixed to prevent movement or slipping during work. Insufficiently secured workpieces may lead to inaccurate results or injuries.

• Distance from body and tool: When striking with a hammer or similar tools, maintain sufficient distance from your body to avoid injuries from possible rebound.

• Secure grip: Hold the seaming tool firmly to prevent slipping or uncontrolled movements. An insecure grip may cause the tool to slip and lead to injuries.

• Controlled strikes: When working with a hammer or similar tools, apply even, controlled strikes. Excessive or uncontrolled blows may damage the workpiece or destroy the tool.

• Correct use of the tool: Use the bossing hammer, seaming iron or plastic hammer only in the designated area of the workpiece to create precise seam lines. Using the tool in the wrong area may deform the workpiece.

Specific Instructions for Individual Tools:

• Bossing hammer: This tool is often used for working sheet metal or metals. Ensure that the surface being struck is evenly supported. Improper handling may deform the material or damage the tool.

• Seaming iron: When using a seaming iron for shaping or embossing metal, ensure that the workpiece is well supported. Strikes with excessive force may cause cracks in the material.

• Seaming board: The seaming board should always be used on a stable surface to ensure precise and safe seaming. Ensure proper storage before and after use.

• Plastic hammer: Often used with more delicate materials or for precise work. Ensure that the hammer head is intact and free from cracks to achieve an even impact.

Maintenance, Care and Storage:

• Regular inspection: Check the condition of seaming tools regularly, especially the striking surfaces and edges. Cracks or wear may render the tool unusable and increase the risk of injury.

• Cleaning after use: After each use, seaming tools must be cleaned thoroughly to remove residues. Dry the tool well to prevent rust formation.

• Storage: Store seaming tools out of reach of children and persons with limited physical, sensory or mental abilities, in a safe, dry place such as a toolbox or tool wall to prevent accidents and damage.

Special Notes:

• Avoid improvisation: Use seaming tools exclusively for their intended purpose. Using tools for unsuitable applications may lead to tool breakage or injuries.

• Transport: Ensure that seaming tools are securely fastened during transport and that sharp edges are protected to avoid injuries.

This text has been partially translated with the support of AI technology.