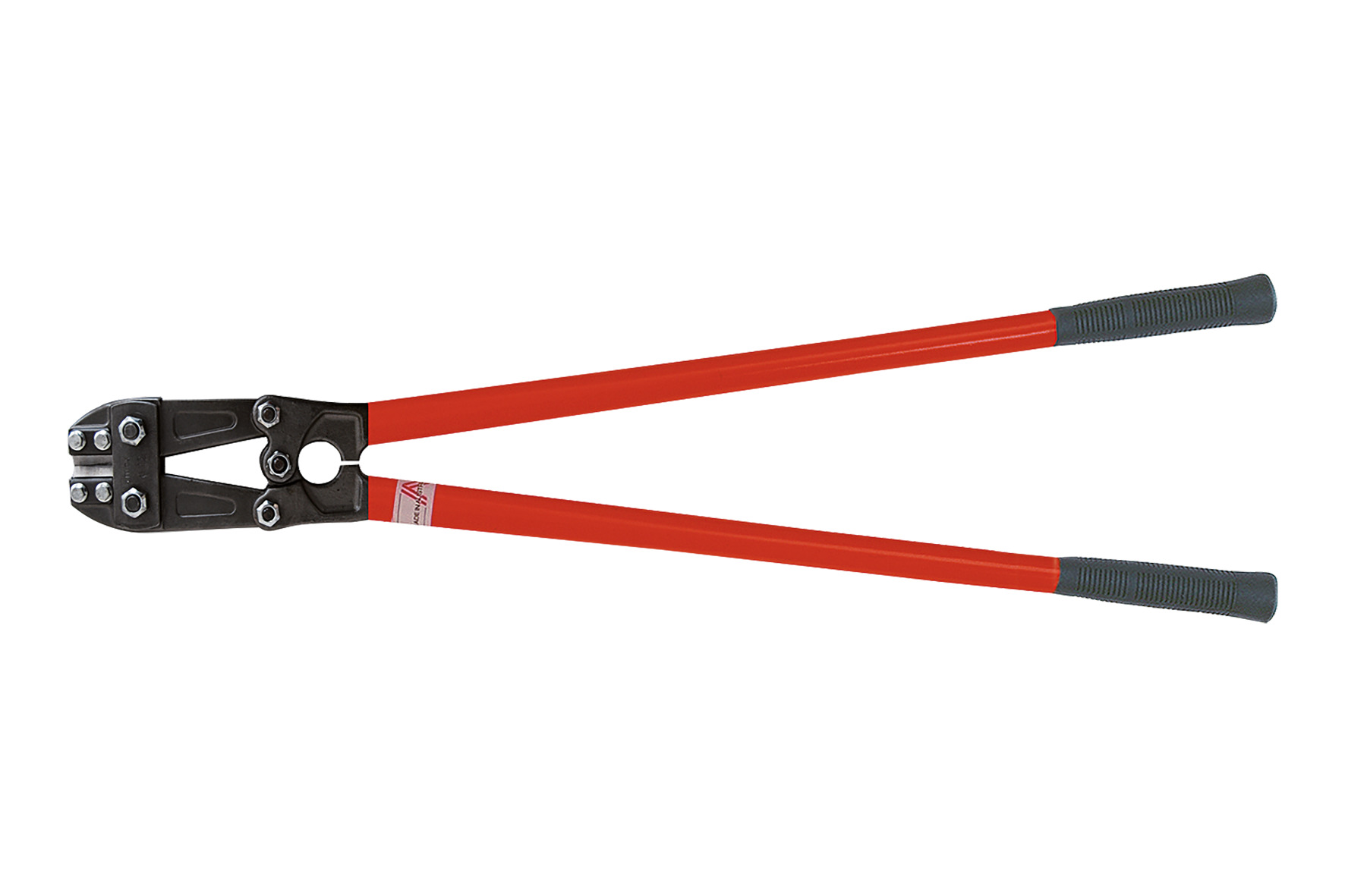

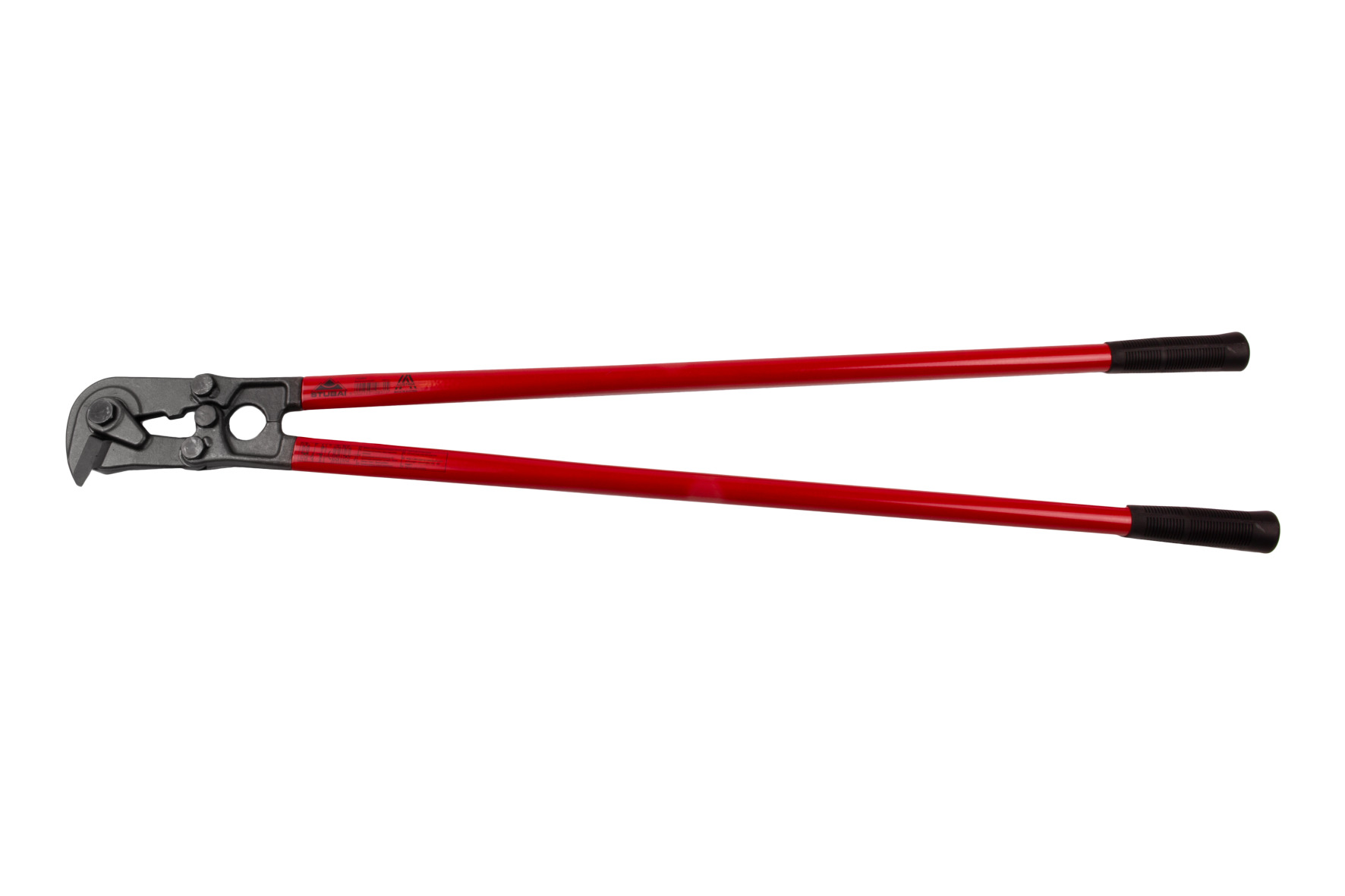

1131 Boltcutter powerline

With interchangeable triangular cutting edges. Forged of special steel, cutting edge made of high-alloy steel. Powder-coated tube steel handles, for high tensile structural steel up to 12 mm Ø (1570 N/mm²) or spring steel up to 10 mm Ø (1760 N/mm²).

Advantages:

- better access to the cutting material, deeper insertion

- less breaking possibility on edges, due to more stable cutting edge

- easy handling with less force necessary

- no twisting on the handles

- better lever transmission

- very balanced weight (fatigue-free working)

- straight handles

- better handling in every working position

- highest quality on triangular cutting edges

- cutting blades are fully adjustable

- long service life of the cutting edges

- no lateral twisting on handles possible

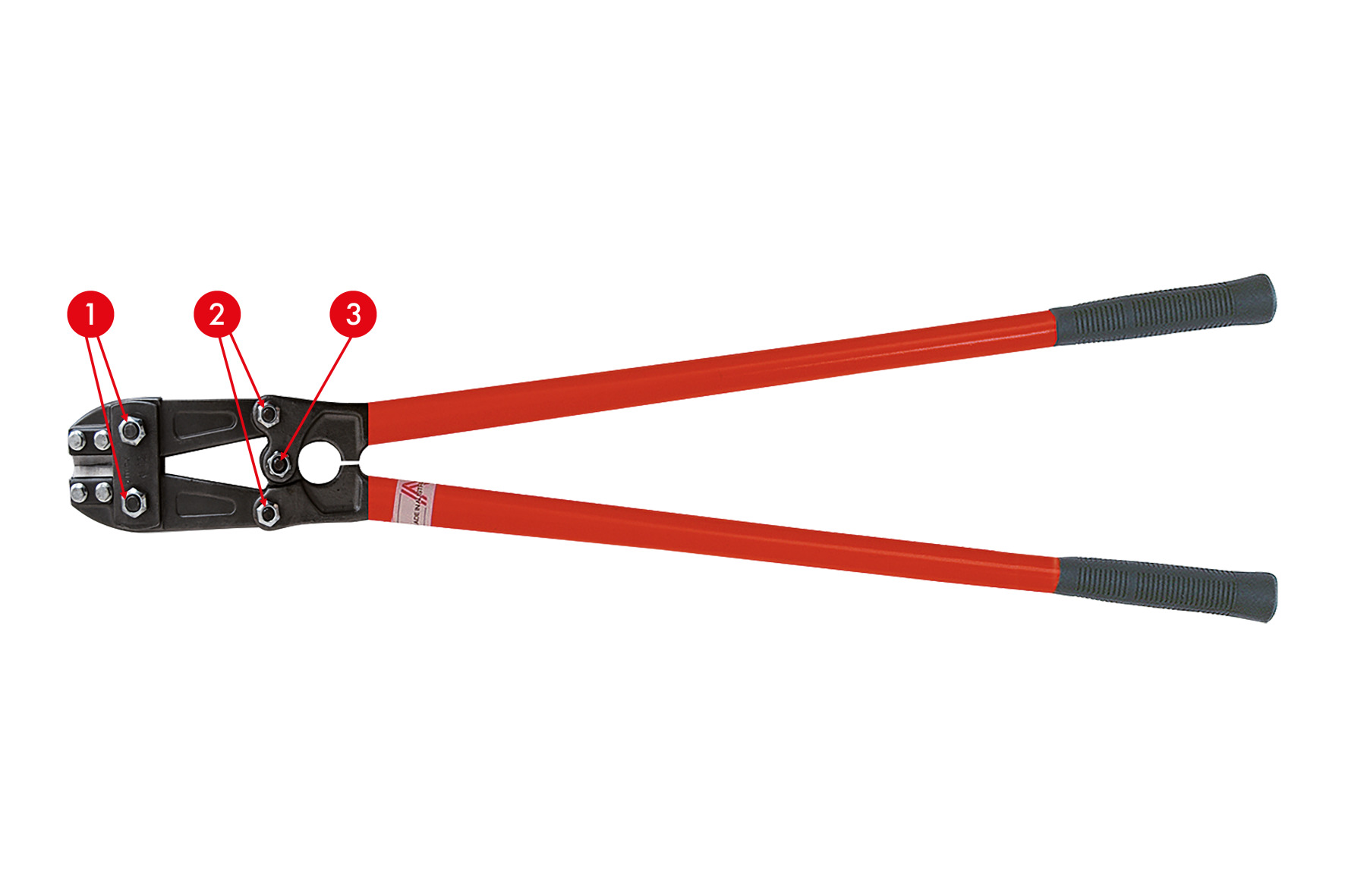

Screws according to illustration:

1. Cylinder screw

2. Eccentric screw

3. Joint screw

| Item No | Designation | Weight | Length | Maximum cutting diameter at 750 N/mm2 | Maximum cutting diameter at 1250 N/mm2 | Spare Parts | Accessories |

|---|---|---|---|---|---|---|---|

| 113105 | Boltcutter powerline 920 mm | 5000 g | 920 mm | 12 mm | 10 mm | Array | Array |

Manufacturer information (GPSR)

STUBAI ZMV GmbH

Dr. Kofler Straße 1

A-6166 Fulpmes

Phone: +43 5225 6960 211

Email: office@stubai.com

Safety Instructions for Bolt Cutters

General Information:

• Suitable tool: Always use bolt cutters specifically designed for the respective task. Using an unsuitable tool increases the risk of accidents and can make the work more difficult.

• Bolt cutters may only be used by persons with limited physical, sensory or mental abilities, or lacking experience and/or knowledge, if they are supervised by a person responsible for their safety, have received instructions on how to use bolt cutters, and have understood the resulting hazards.

• Children may only use bolt cutters if they are over 8 years old and are supervised by a person responsible for their safety, have received instructions on how to use bolt cutters, and have understood the resulting hazards.

• Keep packaging films away from children; risk of suffocation!

Intended Use:

• Safety is only ensured when the tool is used as intended. Use the tool exclusively for its designated purpose.

• Use according to instructions: Bolt cutters are specifically designed for cutting bolts, wire and similar materials.

Improper Use:

• Use as a lever or chisel, as well as twisting motions during cutting, is not permitted. Do not use bolt cutters for cutting hard or unsuitable materials, as this may damage the tool and increase the risk of injury.

Inspection Before Use:

• Ensure tool integrity: Check all bolt cutters before use for visible damage such as cracks in the handle, bent blades, breaks or loose parts.

• Do not use damaged tools: Defective tools must not be used, as they increase the risk of accidents.

Personal Protective Equipment:

• Wear safety goggles: Use safety goggles to protect yourself from chipping material.

• Hand protection: Wear robust work gloves that provide a secure grip and protect against splinters or skin injuries.

• Safety footwear: Wear safety shoes with a metal or plastic toe cap to protect your toes.

Specific Safety Instructions During Use:

• Use only for suitable materials: Use the bolt cutter exclusively for its intended applications, such as cutting wire, bolts or nails.

• Do not use the bolt cutter for materials that are too thick or too hard, such as steel cables or very thick pipes, as this may damage the tool and endanger the user.

• Keep hands and fingers away: Keep your hands and fingers away from the blades and cutting area during use. There is a risk of crushing or cutting injuries if the bolt cutter slips or closes abruptly.

• Sharp blades: Bolt cutters have sharp cutting edges that can cause cuts when cutting wire or bolts. Ensure your hands and fingers remain outside the cutting area at all times.

• Avoid excessive force: Cutting hard materials often requires significant force. Avoid applying unnecessary pressure, as this may overload and damage the tool. Apply pressure in a controlled manner to prevent slipping or breakage.

• Proper handling: Always hold the bolt cutter by the grip area and use both hands for better control. Maintain a stable stance to reduce the risk of slipping or injury.

Maintenance, Care and Storage:

• Regular inspection: Check the condition of the bolt cutter regularly, especially the blades and joints, for wear or damage. A damaged blade increases the risk of improper cuts and accidents.

• Cleaning after use: Clean the bolt cutter after use, especially if it has come into contact with dirty materials. Dirt or rust may impair functionality and create unsafe working conditions.

• Storage: Store bolt cutters out of reach of children and persons with limited physical, sensory or mental abilities, in a safe, dry place such as a toolbox or tool wall to prevent accidents and damage.

Special Notes:

• Avoid improvisation: Use bolt cutters exclusively for their intended purpose. Using tools for unsuitable applications may lead to tool breakage or injuries.

• Transport: Ensure that bolt cutters are securely fastened during transport and that sharp edges are protected to avoid injuries.

This text has been partially translated with the support of AI technology.