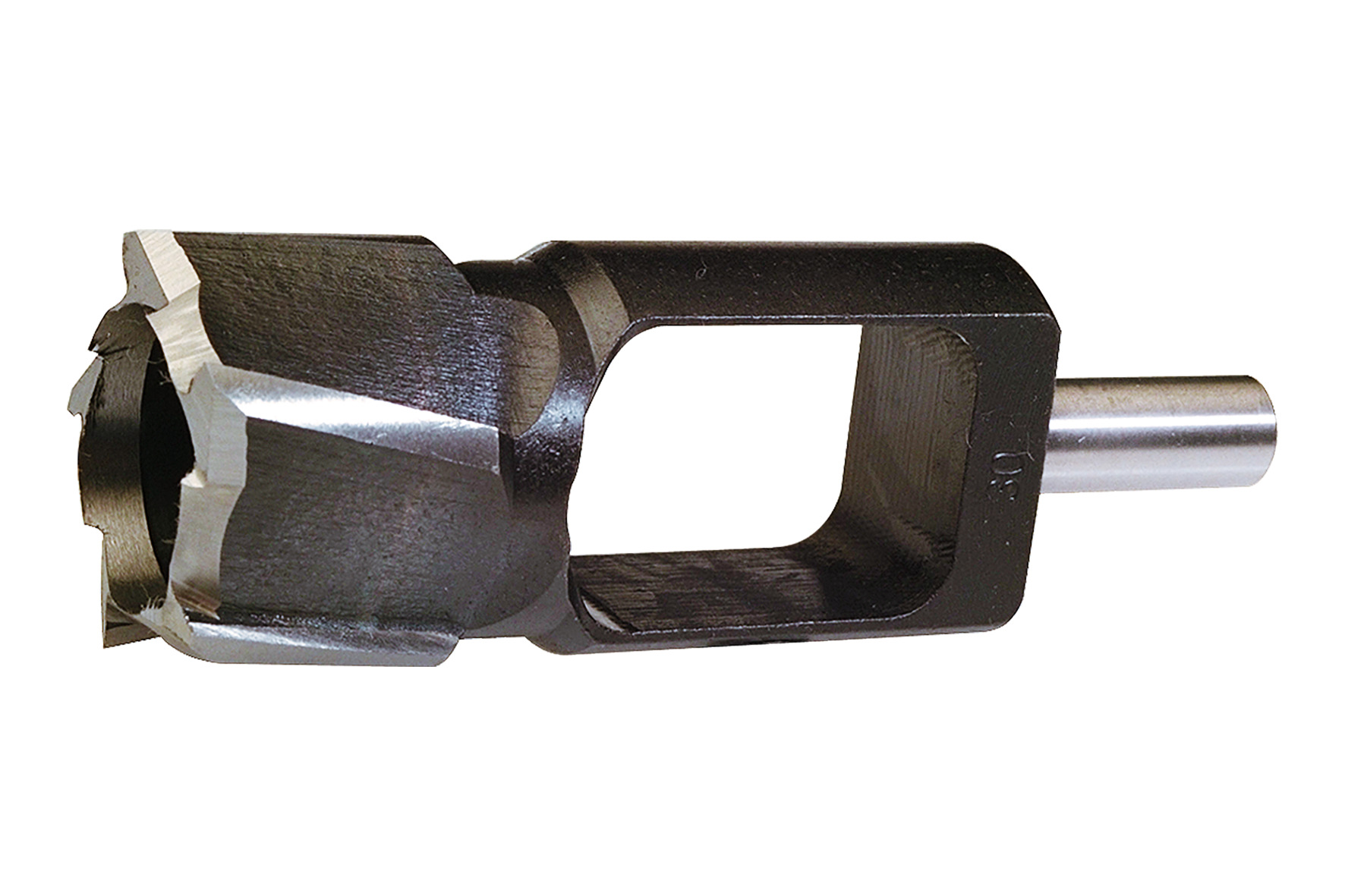

3085 Universal drills

With stepped shank (except Ø 10 mm), brad point, two cutting lips, made of special tool steel, hardened, polished.

For precise, tear-free drilling in soft- and hardwoods, skew and edge drillings, also suitable for drilling machines.

| D1 | L1 | Item No | Designation | Weight | Length | Diameter |

|---|---|---|---|---|---|---|

| 8 mm | 30 mm | 308502 | Universal drill 10 mm | 40 g | 90 mm | 10 mm |

| 8 mm | 30 mm | 308504 | Universal drill 12 mm | 40 g | 90 mm | 12 mm |

| 8 mm | 30 mm | 308506 | Universal drill 14 mm | 40 g | 90 mm | 14 mm |

| 8 mm | 30 mm | 308507 | Universal drill 15 mm | 42 g | 90 mm | 15 mm |

| 8 mm | 30 mm | 308508 | Universal drill 16 mm | 43 g | 90 mm | 16 mm |

| 8 mm | 30 mm | 308509 | Universal drill 18 mm | 50 g | 90 mm | 18 mm |

| 8 mm | 30 mm | 308510 | Universal drill 20 mm | 50 g | 90 mm | 20 mm |

| 10 mm | 30 mm | 308511 | Universal drill 22 mm | 70 g | 90 mm | 22 mm |

| 10 mm | 30 mm | 308512 | Universal drill 24 mm | 74 g | 90 mm | 24 mm |

| 10 mm | 30 mm | 308513 | Universal drill 25 mm | 75 g | 90 mm | 25 mm |

| 10 mm | 30 mm | 308514 | Universal drill 26 mm | 77 g | 90 mm | 26 mm |

| 10 mm | 30 mm | 308515 | Universal drill 28 mm | 91 g | 90 mm | 28 mm |

| 10 mm | 30 mm | 308516 | Universal drill 30 mm | 93 g | 90 mm | 30 mm |

| 10 mm | 30 mm | 308517 | Universal drill 32 mm | 100 g | 90 mm | 32 mm |

| 10 mm | 30 mm | 308518 | Universal drill 34 mm | 102 g | 90 mm | 34 mm |

| 10 mm | 30 mm | 308519 | Universal drill 35 mm | 103 g | 90 mm | 35 mm |

| 10 mm | 30 mm | 308522 | Universal drill 40 mm | 135 g | 90 mm | 40 mm |

| 10 mm | 30 mm | 308523 | Universal drill 45 mm | 180 g | 90 mm | 45 mm |

| 10 mm | 30 mm | 308524 | Universal drill 50 mm | 210 g | 90 mm | 50 mm |

Manufacturer information (GPSR)

MANUFACTURER ACCORDING TO THE EU GENERAL PRODUCT SAFETY REGULATION (GPSR)

STUBAI ZMV GmbH

Dr. Kofler Straße 1

A-6166 Fulpmes

Phone: +43 5225 6960 211

Email: office@stubai.com

Safety Instructions for the Use of Drills / Milling Cutters:

• Suitable drill / milling cutter for the task: Always use a drill or milling cutter specifically designed for the respective task. Using an unsuitable drill or milling cutter increases the risk of accidents and can make the work more difficult.

• Drills and milling cutters may only be used by persons with limited physical, sensory or mental abilities, or lacking experience and/or knowledge, if they are supervised by a person responsible for their safety, have received instructions on how to use hammers, and have understood the resulting hazards.

• Children may only use drills and milling cutters if they are over 8 years old and are supervised by a person responsible for their safety, have received instructions on how to use hammers, and have understood the resulting hazards.

Intended Use:

• Safety is only ensured when the tool is used as intended. Use the drill / milling cutter exclusively for its designated purpose and on the surfaces intended for it.

Improper Use:

• Drilling / milling on unsuitable surfaces is not permitted.

Inspection Before Use:

• Ensure integrity: Check drills and milling cutters before each use for damage such as cracks, loose parts or rust.

• Do not use damaged drills / milling cutters: Defective drills or milling cutters must not be used and must be taken out of service immediately.

•

Personal Protective Equipment:

• Wear safety goggles: Use safety goggles to protect yourself from chipping material.

• Hand protection: Wear robust work gloves that provide a secure grip and protect against splinters or skin injuries.

• Safety footwear: Wear safety shoes with a metal or plastic toe cap to protect your toes.

Specific Safety Instructions for the Use of Awls and Nail Pullers:

• Firm guidance: Guide the awl or nail puller with controlled force and a secure grip. Avoid jerky movements to prevent uncontrolled slipping.

• Do not strike into hands: Never strike directly on the tip of the awl or nail puller. Use a suitable striking tool such as a wooden or rubber mallet to avoid damaging the tool.

Specific Safety Instructions for the Use of Drills & Milling Cutters:

• Hold drilling machines securely: When using a drill with a drilling machine or hand drill, ensure that the tool is held securely in the hand or machine. Slipping can lead to injuries.

• Correct drilling technique: Always apply the drill at a steady, controlled pace to avoid overheating or slipping. Never drill too quickly or with excessive pressure to avoid damaging the tool or the material.

• Sharpen drills regularly: A dull drill requires more pressure and can slip more easily or cut the material unevenly. Keep the drill sharp and in perfect condition.

• Mark the drill hole before working: Always mark the drill hole clearly to ensure precise drilling and safe handling. This helps prevent slipping and unnecessary errors.

Maintenance, Care and Storage:

• Regular inspection: Ensure that all drills and milling cutters are regularly checked for wear or damage. Tools with cracks or other defects must be removed from service immediately and replaced or repaired.

• Cleaning after use: Keep drills and milling cutters clean and free from dust, resin or other residues. Contaminated tools can impair handling and increase the risk of malfunction.

• Storage: Store tools out of reach of children and persons with limited physical, sensory or mental abilities, in a safe, dry place such as a toolbox or tool wall to prevent accidents and damage.

Special Notes:

• No improvisation: Never use drills and milling cutters for tasks for which they are not intended. Improvised solutions can damage the tool and cause serious injuries.

• Avoid overloading: Do not use drills and milling cutters beyond their specified capacity. Overloading the tool can lead to damage and accidents.

• Precise markings: Ensure that precise markings are made on the wood or other material before drilling or milling to facilitate the work and avoid errors.

• Transport: Ensure that tools are securely fastened during transport and that sharp edges are protected to avoid injuries.

This text has been partially translated with the support of AI technology.

STUBAI ZMV GmbH

Dr. Kofler Straße 1

A-6166 Fulpmes

Phone: +43 5225 6960 211

Email: office@stubai.com

Safety Instructions for the Use of Drills / Milling Cutters:

• Suitable drill / milling cutter for the task: Always use a drill or milling cutter specifically designed for the respective task. Using an unsuitable drill or milling cutter increases the risk of accidents and can make the work more difficult.

• Drills and milling cutters may only be used by persons with limited physical, sensory or mental abilities, or lacking experience and/or knowledge, if they are supervised by a person responsible for their safety, have received instructions on how to use hammers, and have understood the resulting hazards.

• Children may only use drills and milling cutters if they are over 8 years old and are supervised by a person responsible for their safety, have received instructions on how to use hammers, and have understood the resulting hazards.

Intended Use:

• Safety is only ensured when the tool is used as intended. Use the drill / milling cutter exclusively for its designated purpose and on the surfaces intended for it.

Improper Use:

• Drilling / milling on unsuitable surfaces is not permitted.

Inspection Before Use:

• Ensure integrity: Check drills and milling cutters before each use for damage such as cracks, loose parts or rust.

• Do not use damaged drills / milling cutters: Defective drills or milling cutters must not be used and must be taken out of service immediately.

•

Personal Protective Equipment:

• Wear safety goggles: Use safety goggles to protect yourself from chipping material.

• Hand protection: Wear robust work gloves that provide a secure grip and protect against splinters or skin injuries.

• Safety footwear: Wear safety shoes with a metal or plastic toe cap to protect your toes.

Specific Safety Instructions for the Use of Awls and Nail Pullers:

• Firm guidance: Guide the awl or nail puller with controlled force and a secure grip. Avoid jerky movements to prevent uncontrolled slipping.

• Do not strike into hands: Never strike directly on the tip of the awl or nail puller. Use a suitable striking tool such as a wooden or rubber mallet to avoid damaging the tool.

Specific Safety Instructions for the Use of Drills & Milling Cutters:

• Hold drilling machines securely: When using a drill with a drilling machine or hand drill, ensure that the tool is held securely in the hand or machine. Slipping can lead to injuries.

• Correct drilling technique: Always apply the drill at a steady, controlled pace to avoid overheating or slipping. Never drill too quickly or with excessive pressure to avoid damaging the tool or the material.

• Sharpen drills regularly: A dull drill requires more pressure and can slip more easily or cut the material unevenly. Keep the drill sharp and in perfect condition.

• Mark the drill hole before working: Always mark the drill hole clearly to ensure precise drilling and safe handling. This helps prevent slipping and unnecessary errors.

Maintenance, Care and Storage:

• Regular inspection: Ensure that all drills and milling cutters are regularly checked for wear or damage. Tools with cracks or other defects must be removed from service immediately and replaced or repaired.

• Cleaning after use: Keep drills and milling cutters clean and free from dust, resin or other residues. Contaminated tools can impair handling and increase the risk of malfunction.

• Storage: Store tools out of reach of children and persons with limited physical, sensory or mental abilities, in a safe, dry place such as a toolbox or tool wall to prevent accidents and damage.

Special Notes:

• No improvisation: Never use drills and milling cutters for tasks for which they are not intended. Improvised solutions can damage the tool and cause serious injuries.

• Avoid overloading: Do not use drills and milling cutters beyond their specified capacity. Overloading the tool can lead to damage and accidents.

• Precise markings: Ensure that precise markings are made on the wood or other material before drilling or milling to facilitate the work and avoid errors.

• Transport: Ensure that tools are securely fastened during transport and that sharp edges are protected to avoid injuries.

This text has been partially translated with the support of AI technology.