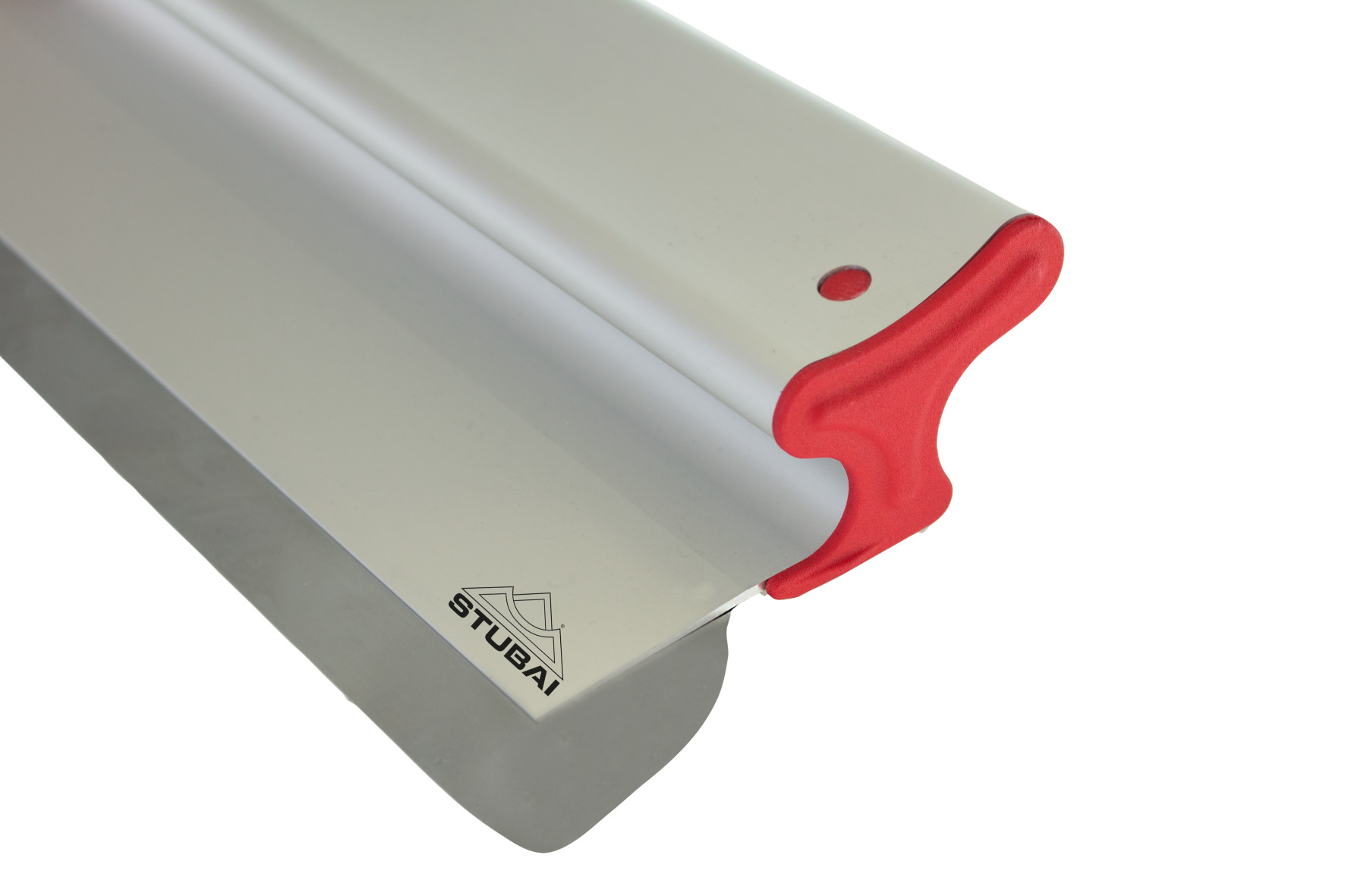

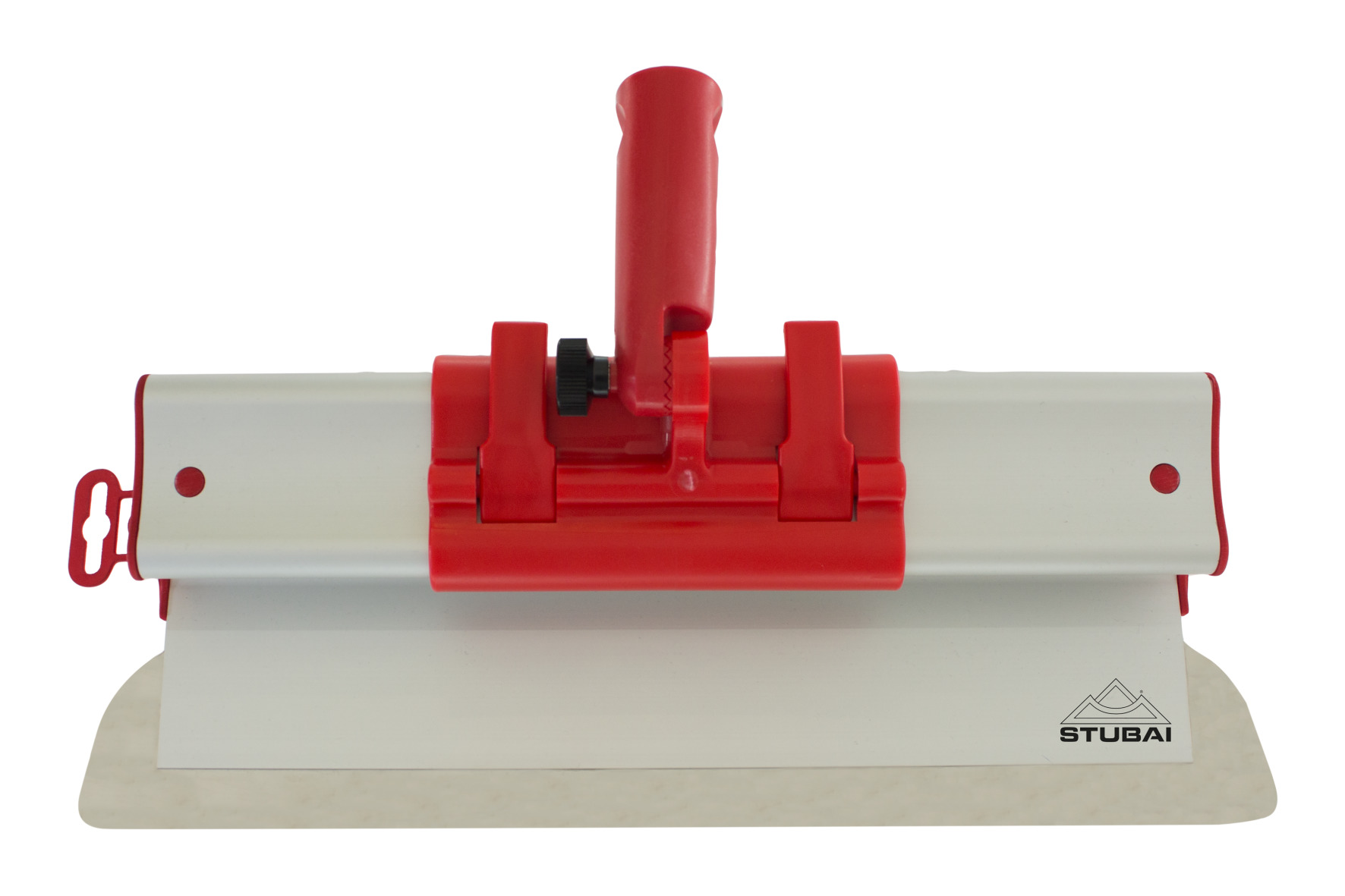

4458 Surface scraper “Planfix”

The STUBAI Planfix features an interchangeable blade system that is suitable for both highly flexible 0.3mm blade blades and stronger 0.5mm blades. The blades are made of high-quality, softened stainless steel for streak-free and smooth surfaces. A lightweight, ergonomically shaped aluminum handle supports fatigue-free work, but can also be guided at an extremely flat angle. High-quality plastering & filling work is done by the STUBAI Planfix even in hard-to-reach places!

| Item No | Designation | Weight | Length | Shape | Spare Parts |

|---|---|---|---|---|---|

| 445805 | Surface scraper "Planfix" 50 mm | 140 g | 50 mm | rounded | Array |

| 445815 | Surface scraper "Planfix" 150 mm | 280 g | 150 mm | rounded | Array |

| 445825 | Surface scraper "Planfix" 250 mm | 500 g | 250 mm | rounded | Array |

| 445840 | Surface scraper "Planfix" 400 mm | 680 g | 400 mm | rounded | Array |

| 445860 | Surface scraper "Planfix" 600 mm | 780 g | 600 mm | rounded | Array |

| 445880 | Surface scraper "Planfix" 800 mm | 1020 g | 800 mm | rounded | Array |

| 445810 | Surface scraper "Planfix" 1000 mm | 1300 g | 1000 mm | rounded | Array |

| 445812 | Surface scraper "Planfix" 1250 mm | 1640 g | 1250 mm | rounded | Array |

| 445820 | Surface scraper "Planfix" 1500 mm | 2000 g | 1500 mm | rounded | Array |

| 445905 | Surface scraper "Planfix" 50 mm | 150 g | 50 mm | angular | Array |

| 445915 | Surface scraper "Planfix" 150 mm | 300 g | 150 mm | angular | Array |

| 445925 | Surface scraper "Planfix" 250 mm | 550 g | 250 mm | angular | Array |

| 445940 | Surface scraper "Planfix" 400 mm | 700 g | 400 mm | angular | Array |

| 445960 | Surface scraper "Planfix" 600 mm | 800 g | 600 mm | angular | Array |

| 445980 | Surface scraper "Planfix" 800 mm | 1100 g | 800 mm | angular | Array |

| 445910 | Surface scraper "Planfix" 1000 mm | 1400 g | 1000 mm | angular | Array |

| 445912 | Surface scraper "Planfix" 1250 mm | 1700 g | 1250 mm | angular | Array |

| 445920 | Surface scraper "Planfix" 1500 mm | 2100 g | 1500 mm | angular | Array |

Manufacturer information (GPSR)

MANUFACTURER ACCORDING TO THE EU GENERAL PRODUCT SAFETY REGULATION (GPSR)

STUBAI ZMV GmbH

Dr. Kofler Straße 1

A-6166 Fulpmes

Phone: +43 5225 6960 211

Email: office@stubai.com

Safety Instructions for Tiling and Masonry Tools

General Information:

• Suitable tool: Always use the tool specifically designed for the respective task. Using an unsuitable tool increases the risk of accidents and can make the work more difficult.

Intended Use:

• Safety is only ensured when the tool is used as intended. Use the tool exclusively for its designated purpose. Tile cutters and tile nippers are intended for tiles, while masonry tools are used for mortar and similar materials. Incorrect use may lead to tool breakage and injuries.

Improper Use:

• The tool is only permitted for use in construction applications. Work only on materials intended for this purpose.

Inspection Before Use:

• Ensure tool integrity: Check all tiling and masonry tools for visible damage such as cracks, breaks or loose parts before use.

• Do not use damaged tools: Defective tools must not be used, as they increase the risk of accidents.

Personal Protective Equipment:

• Wear safety goggles: Use safety goggles to protect yourself from chipping material.

• Hand protection: Wear robust work gloves that provide a secure grip and protect against splinters or skin injuries.

• Safety footwear: Wear safety shoes with a metal or plastic toe cap to protect your toes.

Use:

• Proper handling: Always hold tools by their designated handles to ensure safe and precise operation. Avoid touching the working surfaces of the tools, especially sharp or hard edges.

• Avoid overloading: Ensure that tools are not overloaded. Do not apply excessive pressure to cutting or leverage tools, as this may cause damage and compromise safety.

Specific Instructions for Tiling and Masonry Tools:

• Tile cutters and tile nippers:

o Ensure that the cutting edges are sharp and free from cracks. A damaged tile cutter can cause inaccurate cuts and increase the risk of injury.

o When using nippers, check the tension and functionality of the spring mechanisms. A faulty spring may reduce control over the tool and make work unsafe.

• Masonry and trowel tools:

o Check trowels and spatulas for cracks or loose connections between the handle and the blade. Damaged trowels should be replaced immediately.

o Ensure that the edges of trowels are sharp and free from wear to guarantee precise application of mortar or filler.

o Use masonry trowels only for mortar or similar materials and avoid using them on hard surfaces to prevent tool damage.

o Ensure that trowels are properly cleaned and dried to prevent rust and the accumulation of residues.

o Trowels, especially finishing and notched trowels, have sharp edges. Exercise caution during use and cleaning to avoid cuts.

• Hammers and chisels:

o Regularly inspect hammer heads and chisels for cracks or wear. A damaged hammer head may chip and cause serious injuries.

o Chisels should always be held correctly in a chisel holder or by the stable handle. Never use chisels with broken or damaged tips.

o Wear safety goggles and suitable gloves when working with chisels to reduce the risk of injuries from flying splinters.

Maintenance, Care and Storage:

• Cleaning after use: After each use, tiling and masonry tools must be thoroughly cleaned to remove residues of mortar, paint or tile adhesive. Use suitable cleaning agents to avoid damaging the tools.

• Sharpening: Keep cutting tools such as tile cutters and chisels sharp to increase efficiency and minimize the risk of slipping. Sharpen tools regularly to ensure safe and precise use.

• Rust protection: Protect metal parts of the tools from moisture to prevent rust. Apply rust protection products if necessary.

• Storage: Store tools out of reach of children and persons with limited physical, sensory or mental abilities, in a safe, dry place such as a toolbox or tool wall to prevent accidents and damage.

Special Notes:

• Avoid improvisation: Use tiling and masonry tools exclusively for their intended purpose. Using tools for unsuitable applications may lead to tool breakage or injuries.

• Transport: Ensure that tiling or masonry tools are securely fastened during transport and that sharp edges are protected to avoid injuries.

This text has been partially translated with the support of AI technology.

STUBAI ZMV GmbH

Dr. Kofler Straße 1

A-6166 Fulpmes

Phone: +43 5225 6960 211

Email: office@stubai.com

Safety Instructions for Tiling and Masonry Tools

General Information:

• Suitable tool: Always use the tool specifically designed for the respective task. Using an unsuitable tool increases the risk of accidents and can make the work more difficult.

Intended Use:

• Safety is only ensured when the tool is used as intended. Use the tool exclusively for its designated purpose. Tile cutters and tile nippers are intended for tiles, while masonry tools are used for mortar and similar materials. Incorrect use may lead to tool breakage and injuries.

Improper Use:

• The tool is only permitted for use in construction applications. Work only on materials intended for this purpose.

Inspection Before Use:

• Ensure tool integrity: Check all tiling and masonry tools for visible damage such as cracks, breaks or loose parts before use.

• Do not use damaged tools: Defective tools must not be used, as they increase the risk of accidents.

Personal Protective Equipment:

• Wear safety goggles: Use safety goggles to protect yourself from chipping material.

• Hand protection: Wear robust work gloves that provide a secure grip and protect against splinters or skin injuries.

• Safety footwear: Wear safety shoes with a metal or plastic toe cap to protect your toes.

Use:

• Proper handling: Always hold tools by their designated handles to ensure safe and precise operation. Avoid touching the working surfaces of the tools, especially sharp or hard edges.

• Avoid overloading: Ensure that tools are not overloaded. Do not apply excessive pressure to cutting or leverage tools, as this may cause damage and compromise safety.

Specific Instructions for Tiling and Masonry Tools:

• Tile cutters and tile nippers:

o Ensure that the cutting edges are sharp and free from cracks. A damaged tile cutter can cause inaccurate cuts and increase the risk of injury.

o When using nippers, check the tension and functionality of the spring mechanisms. A faulty spring may reduce control over the tool and make work unsafe.

• Masonry and trowel tools:

o Check trowels and spatulas for cracks or loose connections between the handle and the blade. Damaged trowels should be replaced immediately.

o Ensure that the edges of trowels are sharp and free from wear to guarantee precise application of mortar or filler.

o Use masonry trowels only for mortar or similar materials and avoid using them on hard surfaces to prevent tool damage.

o Ensure that trowels are properly cleaned and dried to prevent rust and the accumulation of residues.

o Trowels, especially finishing and notched trowels, have sharp edges. Exercise caution during use and cleaning to avoid cuts.

• Hammers and chisels:

o Regularly inspect hammer heads and chisels for cracks or wear. A damaged hammer head may chip and cause serious injuries.

o Chisels should always be held correctly in a chisel holder or by the stable handle. Never use chisels with broken or damaged tips.

o Wear safety goggles and suitable gloves when working with chisels to reduce the risk of injuries from flying splinters.

Maintenance, Care and Storage:

• Cleaning after use: After each use, tiling and masonry tools must be thoroughly cleaned to remove residues of mortar, paint or tile adhesive. Use suitable cleaning agents to avoid damaging the tools.

• Sharpening: Keep cutting tools such as tile cutters and chisels sharp to increase efficiency and minimize the risk of slipping. Sharpen tools regularly to ensure safe and precise use.

• Rust protection: Protect metal parts of the tools from moisture to prevent rust. Apply rust protection products if necessary.

• Storage: Store tools out of reach of children and persons with limited physical, sensory or mental abilities, in a safe, dry place such as a toolbox or tool wall to prevent accidents and damage.

Special Notes:

• Avoid improvisation: Use tiling and masonry tools exclusively for their intended purpose. Using tools for unsuitable applications may lead to tool breakage or injuries.

• Transport: Ensure that tiling or masonry tools are securely fastened during transport and that sharp edges are protected to avoid injuries.

This text has been partially translated with the support of AI technology.